Custom-sized mirrors for contractors

Of course. Here is a comprehensive guide to custom-sized mirrors for contractors, covering key considerations, ordering process, and tips for successful installation.

Custom-Sized Mirrors for Contractors: A Professional’s Guide

For contractors, sourcing and installing custom mirrors is a common task in bathrooms, gyms, lobbies, and luxury homes. Getting it right requires attention to detail in measurement, specification, and installation.

1. Key Considerations Before Ordering

-

Precise Measurements: This is the most critical step. Measure the height and width in at least three different places (top, middle, bottom for width; left, center, right for height). Account for any out-of-plumb walls. Always specify if measurements are to the nearest 1/8″ or 1/16″ to ensure a perfect fit. Never assume the opening is perfectly square.

-

Mirror Thickness: Typically ranges from 1/8″ (3mm) to 1/4″ (6mm).

-

1/8″ (3mm): Standard for most residential wall-mounted applications. Lighter and more cost-effective.

-

3/16″ (5mm): A good middle ground, offering more rigidity for larger sizes.

-

1/4″ (6mm): Recommended for large mirrors (e.g., over 8-10 sq. ft.), door/wall-mounted pivot mirrors, or areas requiring extra durability and less flex. It provides a more substantial, high-end look.

-

-

Edgework (Seaming/Polishing): How the edges of the glass are finished.

-

Seamed (Pencil Polish): A basic, slightly rounded edge that removes the sharpness. Standard and functional for most applications where the edge will be against a wall or within a frame.

-

Polished Edge (Full Polish): A smooth, glossy, beautifully finished edge. Essential for any exposed edge, such as on a freestanding mirror, a mirror with clipped brackets, or where the mirror is a design feature. It is more expensive but looks professional.

-

Bevelled Edge: A decorative angled cut along the edge. Adds a classic, elegant touch but increases cost significantly. Can be various widths.

-

-

Backing and Coating:

-

Clear Silver: The standard backing. Not recommended for high-humidity areas as it can degrade over time (edge corrosion/black edge).

-

Copper-Free/”Wet Area” Backing: A must for bathrooms, spas, or any high-moisture environment. This dual-coating process (typically copper + paint) provides superior protection against moisture penetration, preventing black edge and delamination.

-

-

Mounting Method: Decide this before ordering, as it affects the mirror’s specifications.

-

J-Channel/Clips: Most common. The mirror sits in a metal channel at the bottom and is secured with side clips. Requires precise measurements.

-

French Cleat or Z-Clip: Excellent for heavy mirrors. Provides a very secure, hidden mounting solution.

-

Adhesive (Mastic): Mirror is glued directly to the wall. Creates a sleek, frameless look but requires a perfectly flat, prepared wall. Never use adhesive alone on a mirror larger than 6-8 sq. ft.; combine with clips for safety.

-

Silicone: Often used in conjunction with clips to provide extra support and prevent shifting.

-

2. The Ordering Process

-

Source a Reputable Glass & Mirror Supplier: Look for a local fabricator with good reviews that specializes in serving contractors. They will provide better pricing, expertise, and reliability than a big-box store.

-

Provide Clear Specifications: Give them a cut sheet or clear document with:

-

Exact Height x Width (in inches or millimeters).

-

Desired Thickness (e.g., 1/4″).

-

Edgework (e.g., “All edges fully polished”).

-

Backing (e.g., “Copper-free wet area backing”).

-

Any special notes (e.g., “Notch for electrical outlet,” “Polished hole for faucet,” “Tempered for safety”).

-

-

Get a Formal Quote: The quote should break out the cost of the raw glass, cutting/fabrication (edgework), any special coatings, and delivery fees.

-

Lead Time: Custom mirrors typically take 5-10 business days to fabricate, depending on the supplier’s workload.

3. Installation Best Practices

-

Handle with Care: Always wear cut-resistant gloves. Never place weight on the center of a large, unsupported mirror.

-

Check the Product: Upon delivery, inspect the mirror for chips, cracks, or imperfections in the edgework before the installer leaves.

-

Wall Preparation: The wall must be clean, dry, and flat. For adhesive mounting, use a level to mark placement.

-

Safety First: For large or heavy mirrors, use a mechanical mounting system (clips, cleat) as the primary support, with adhesive or silicone as a secondary stabilizer.

-

Code Compliance: In many areas, any mirror installed in a commercial setting or in a residential bathroom must be made of safety glass (tempered or laminated). Check your local building codes. Tempering is required if the mirror is within a certain distance of a door, shower, or floor.

4. Common Project Types & Specs

| Project Type | Recommended Thickness | Key Features & Tips |

|---|---|---|

| Standard Bathroom Wall | 1/8″ (3mm) or 3/16″ (5mm) | Wet area backing is critical. Use J-channel and clips. Polish edges if side clips are exposed. |

| Large Master Bath/Gym Wall | 1/4″ (6mm) | Reduces “oil-canning” (waviness). Use a sturdy French cleat or heavy-duty clips. |

| Medicine Cabinet Insert | 1/8″ (3mm) | Measure the rebate (recess) in the cabinet door precisely. Seamed edges are usually fine. |

| Pivot/Swing Mirror | 1/4″ (6mm) | Must be tempered. Requires drilled holes for pivot hardware. All exposed edges must be fully polished. |

| Decorative Framed Mirror | 1/8″ (3mm) | The frame provides all support. Standard seamed edges are acceptable as they will be hidden. |

| Commercial Lobby/Retail | 1/4″ (6mm) | Often must be tempered by code. High-traffic area demands durability. Secure mounting is a must. |

5. Tips for Working with Clients

-

Educate Them: Explain the difference between standard and wet-area backing. Many clients don’t know why their builder-grade bathroom mirrors failed.

-

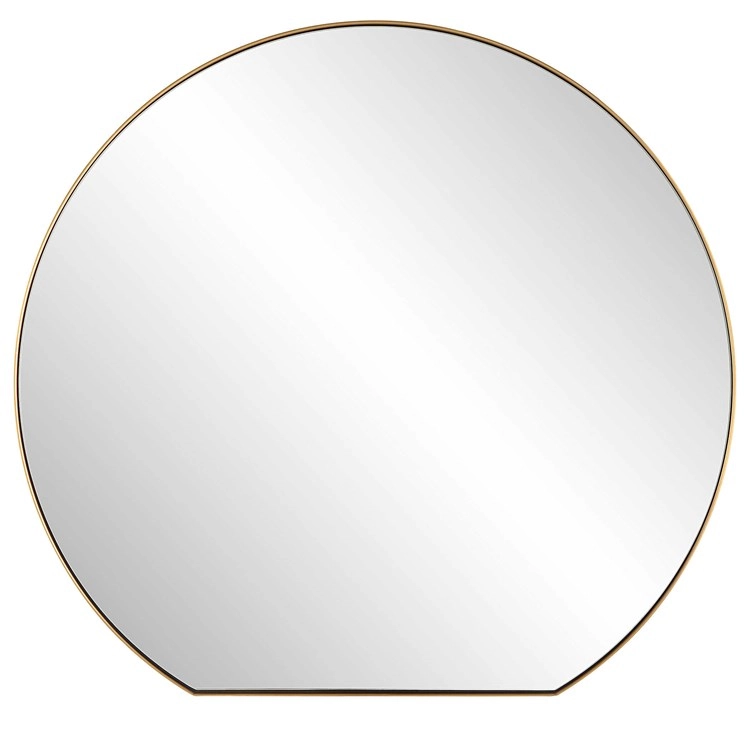

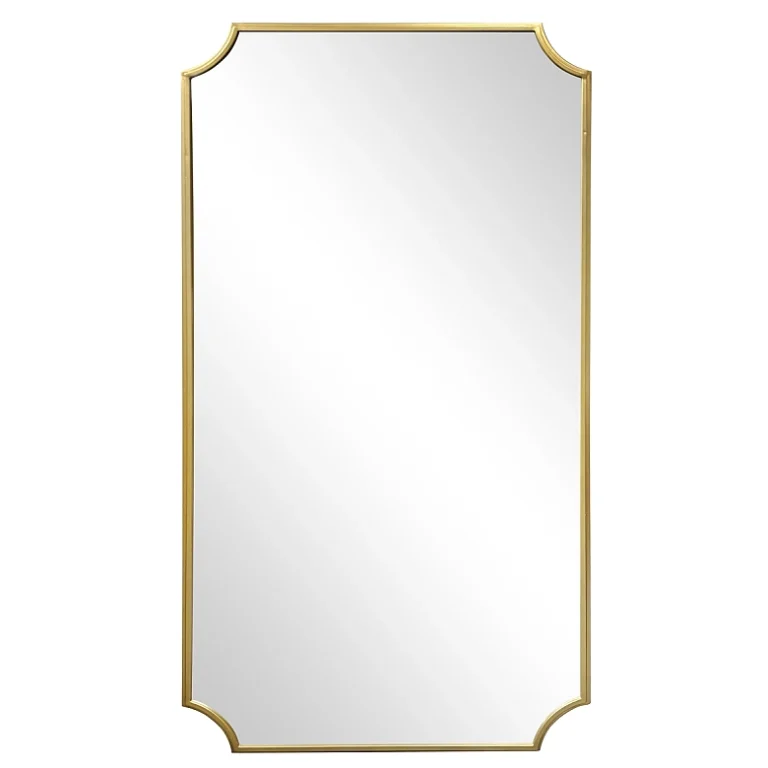

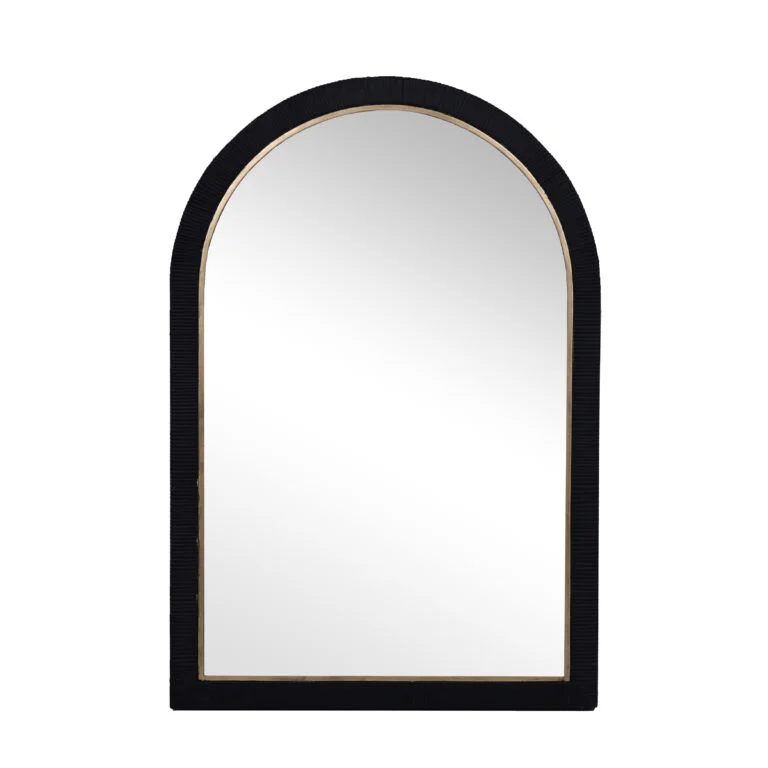

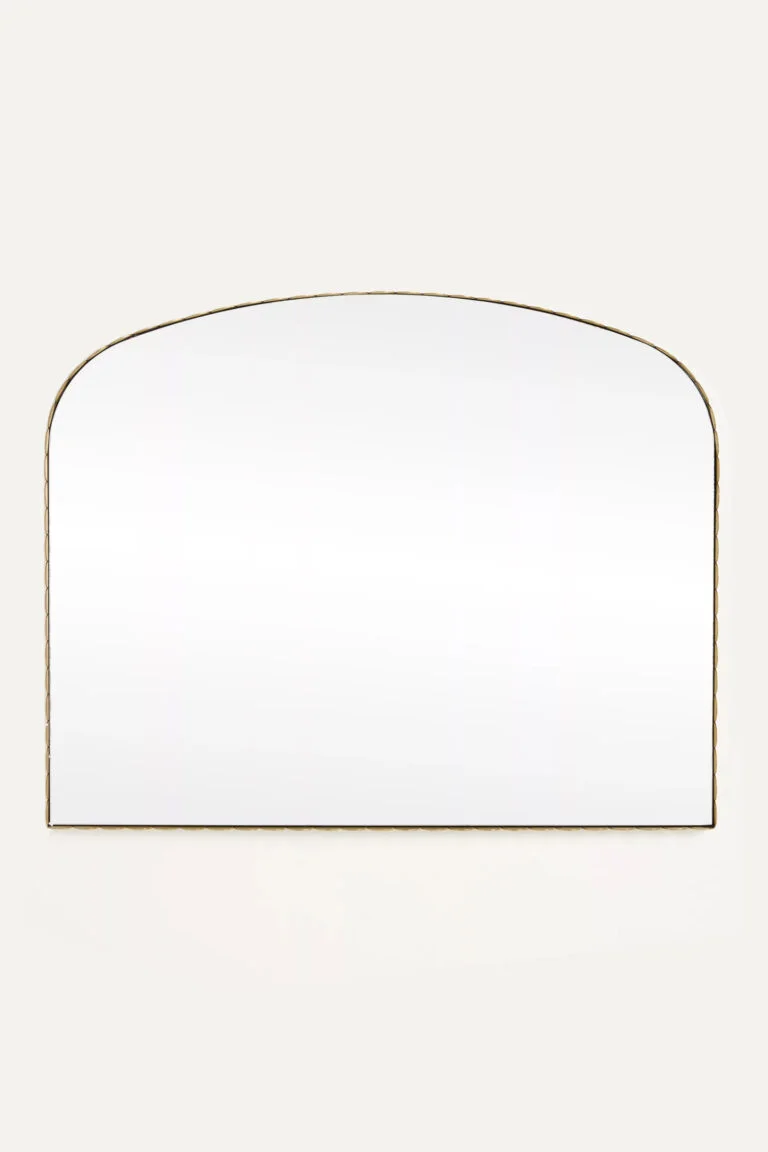

Show Options: Have samples or photos of different edgework (seamed vs. polished vs. beveled) to help them visualize the final product.

-

Manage Expectations: Clarify that custom glass is a fabricated product with a lead time. A small imperfection in the silvering (a “seed”) is normal and not a defect.

-

Warranty: Understand your supplier’s warranty on the mirror’s backing and craftsmanship.

Final Pro Tip: Build a strong relationship with a single, reliable glass and mirror fabricator. Their expertise will save you time and money on measurements, specifications, and problem-solving on complex jobs. They are an invaluable partner for any contractor.

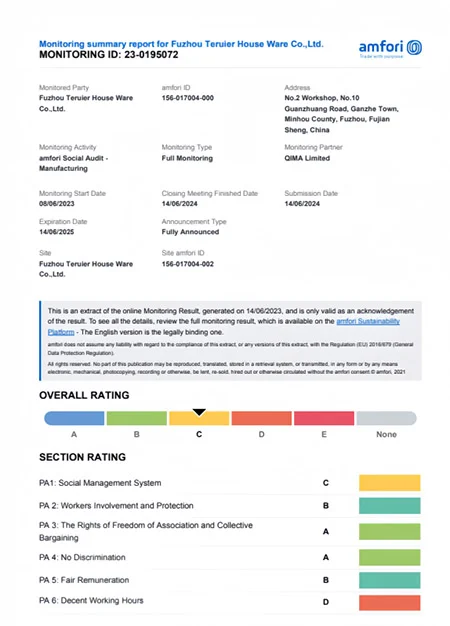

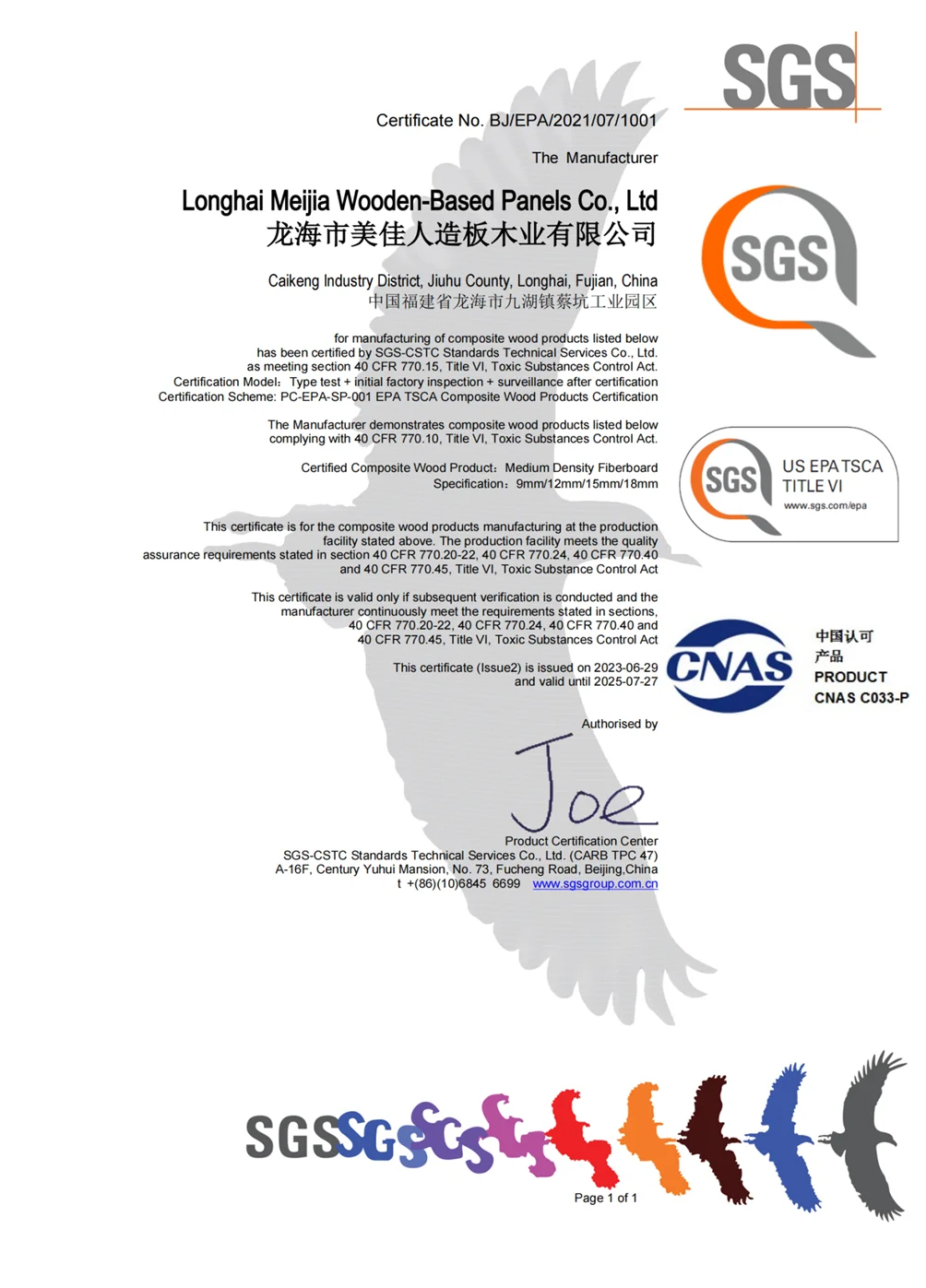

Generally speaking, our order requirements are as follows: the minimum order quantity (MOQ) for large items is 50 pieces, for regular items it is 100 pieces, for small items it is 500 pieces, and for very small items (such as ceramic decorations) the MOQ is 1,000 pieces. Orders exceeding $100,000 will receive a 5% discount. The delivery timeline is determined based on the specific order quantity and production schedule. Typically, we are able to complete delivery within two months.

-scaled.jpg)