- Mirror Manufacturer USA-Custom Bathroom & LED Mirror Factory

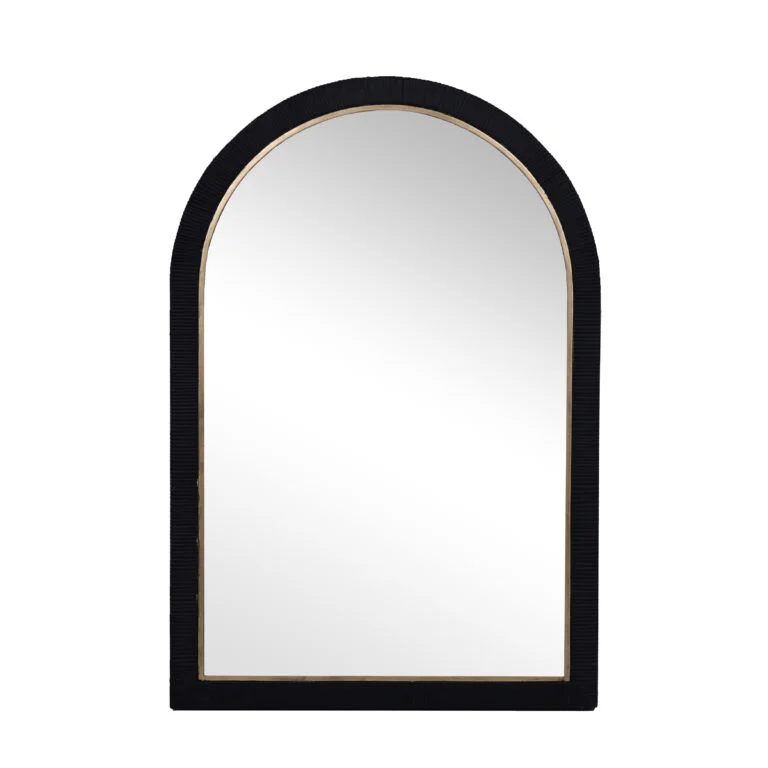

- Mirrors French

- Mirror Austrian

- Canadian mirrors

- Mirrors British

- Mirror Dutch

- Mirror Hungarian

- Mirror Belgian

- Mirror Slovak

- Mirror Luxembourg

- Mirror Romanian

- Mirror Swiss

- Mirror Bulgarian

- Mirror Croatian

- Mirror Irish

- Mirror Serbian

- Mirror Swedish

- Mirrors Norwegian

- Mirrors Finnish

- Mirrors Danish

- Mirrors Icelandic

- Mirrors Greek

- Mirrors German

- Maltese mirrors

- Mirrors Italian

- Mirrors Cypriot

- Mirrors Spanish

- Mirrors Polish

- Mirrors Portuguese

- Mirrors Czech

supplier for anti-corrosion mirrors coastal areas Saudi

Why Standard Mirrors Fail in Coastal Climates

Standard silver mirrors utilize a thin layer of silver nitrate protected by copper and paint. However, in coastal areas:

-

Salt Spray: Airborne salt particles are highly corrosive and penetrate microscopic gaps in the mirror’s protective backing.

-

High Humidity: Moisture facilitates electrochemical reactions, accelerating the oxidation of the metal layer.

-

UV Radiation: Intense sun exposure can degrade the protective sealants and paints over time.

This combination leads to “mirror rot” or corrosion, compromising both functionality and aesthetics.

Teruiermirror’s Anti-Corrosion Mirror Solution: Engineered for Durability

As a specialized factory and supplier, we go beyond standard manufacturing. Our anti-corrosion mirrors are built with a multi-layered protective system:

-

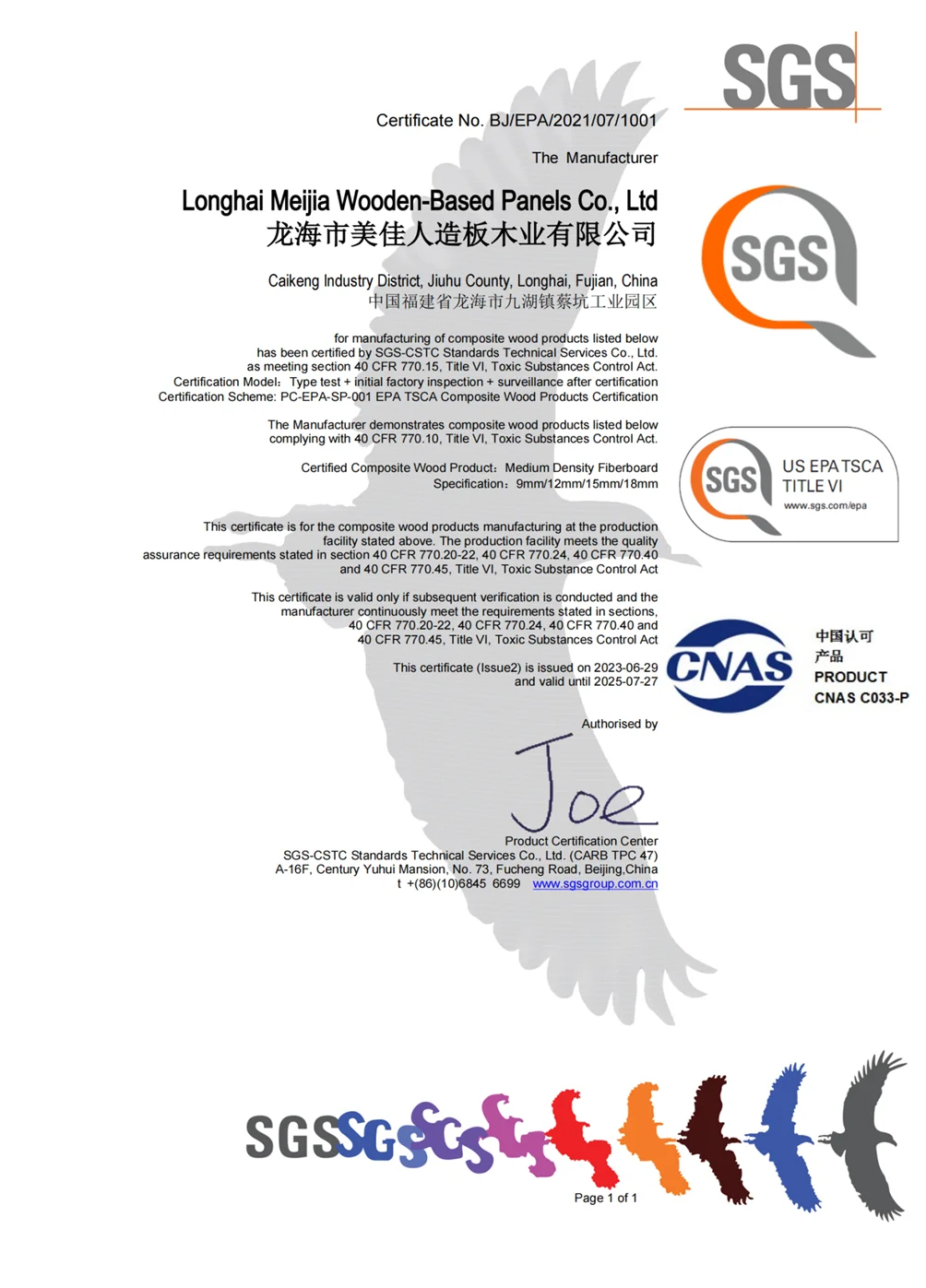

Premium Float Glass: We use high-quality, clear float glass as the base for impeccable reflection.

-

Advanced Silvering Process: Our precise silvering application ensures a uniform, dense layer free from impurities that can initiate corrosion.

-

Dual Protective Copper Layer (Optional): A critical barrier that shields the silver layer from direct exposure.

-

Specialized Anti-Corrosion Paint: This is the key differentiator. We apply a thick, high-solid, acid- and alkali-resistant paint backing. This paint forms an impermeable seal, effectively blocking moisture, salt, and chemical vapors from reaching the metal layers.

-

Robust Edge Sealing: We offer additional edge sealing treatments to provide 360-degree protection, a crucial feature for the extreme conditions of Saudi coastal areas.

Key Applications for Our Mirrors in Saudi Arabia

Our products are essential for any project where durability is non-negotiable:

-

Coastal Hotels & Resorts: Bathrooms, lobbies, spa areas, and outdoor installations.

-

Villas & Residential Complexes: Along the coastlines of Jeddah, Dammam, Al Khobar, and Jubail.

-

Marine & Waterfront Facilities: Restaurants, clubs, marinas, and ports.

-

Healthcare & Educational Institutions: Hospitals and schools near the sea that require hygienic, long-lasting mirrors.

-

Industrial Facilities: Plants and factories located in industrial coastal cities.

Why Choose Teruiermirror as Your Supplier in Saudi Arabia?

-

In-House Manufacturing: As a direct factory and supplier, we control every step of the production process, ensuring strict quality control and competitive pricing.

-

Proven Expertise in Saudi Market: We understand the specific environmental challenges of the Middle East and have tested our products to perform reliably in them.

-

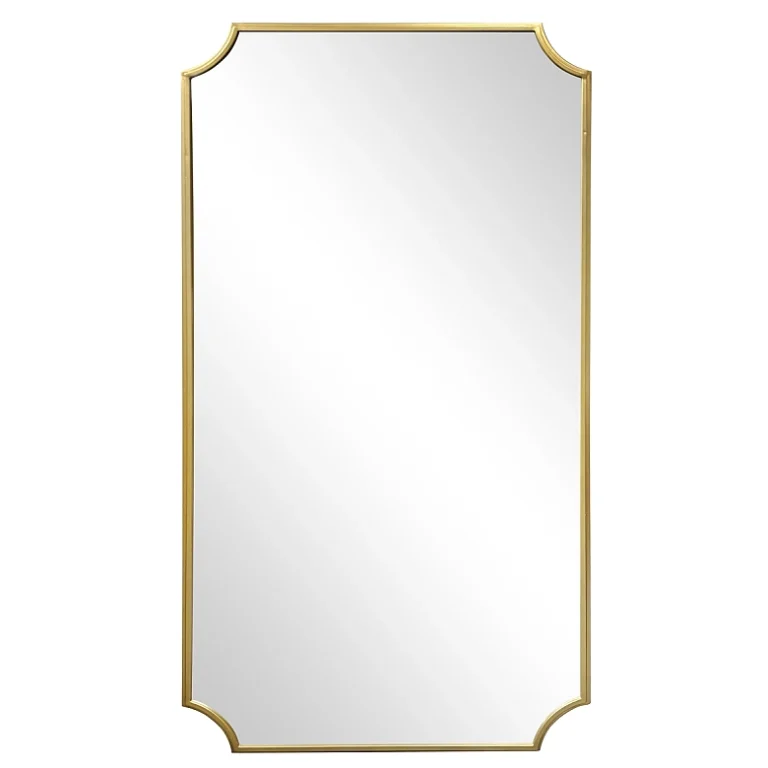

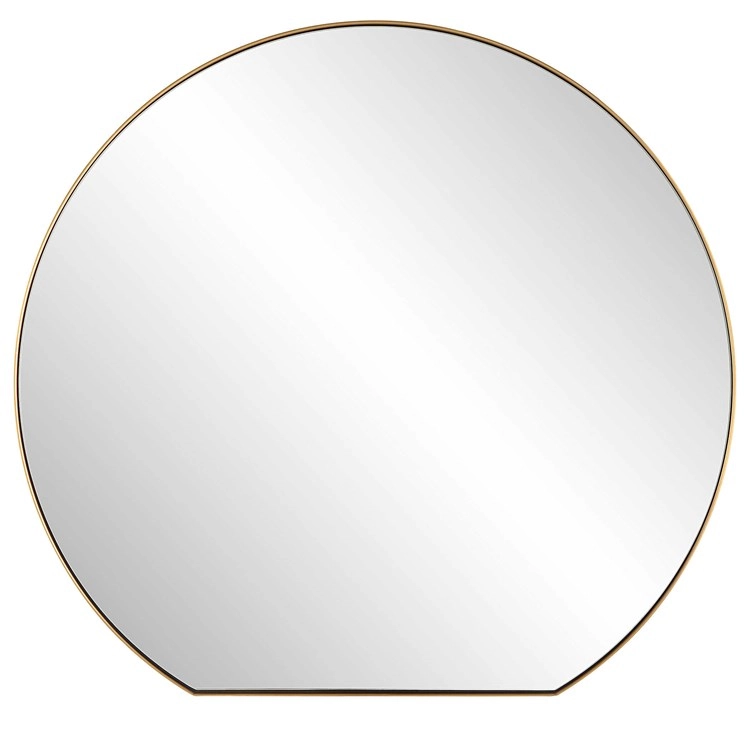

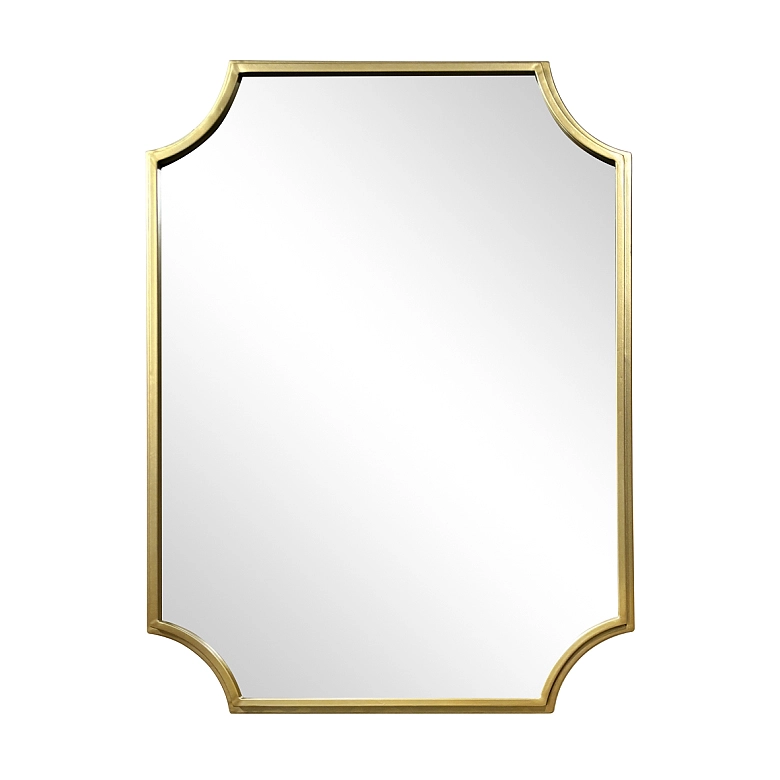

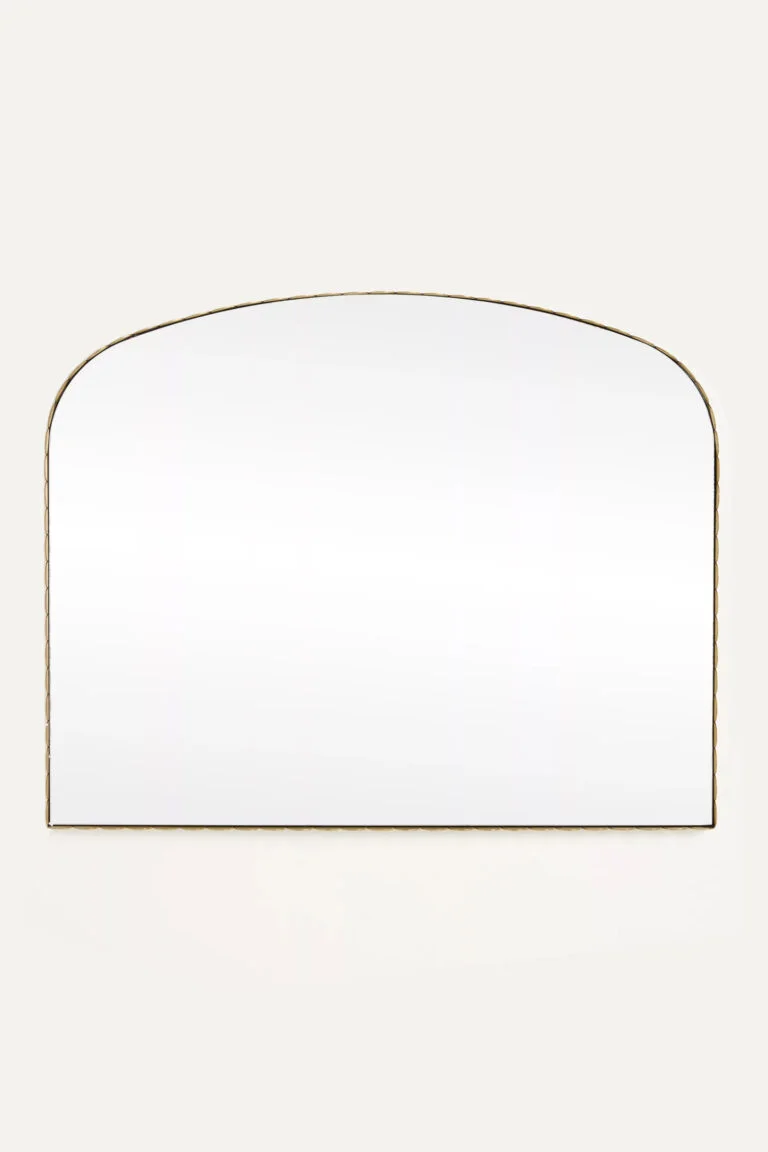

Customization: We offer custom sizes, shapes, thicknesses, and even additional features like demisting capabilities to meet your exact project specifications.

-

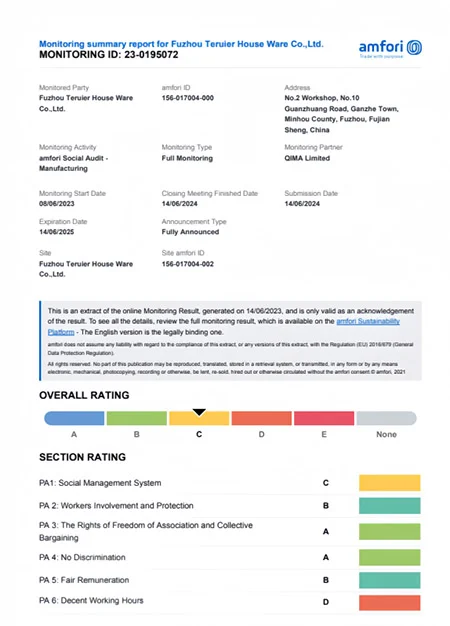

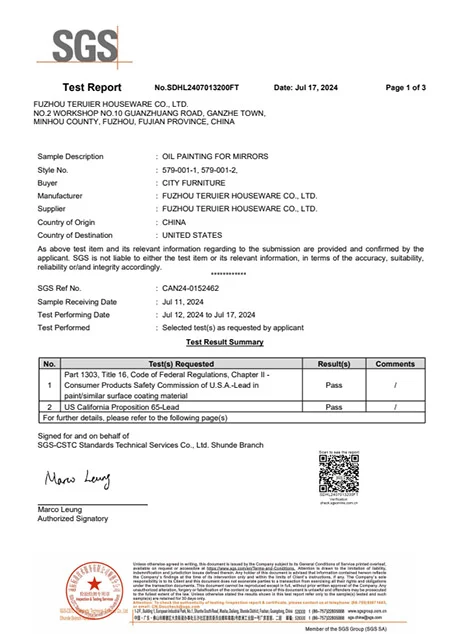

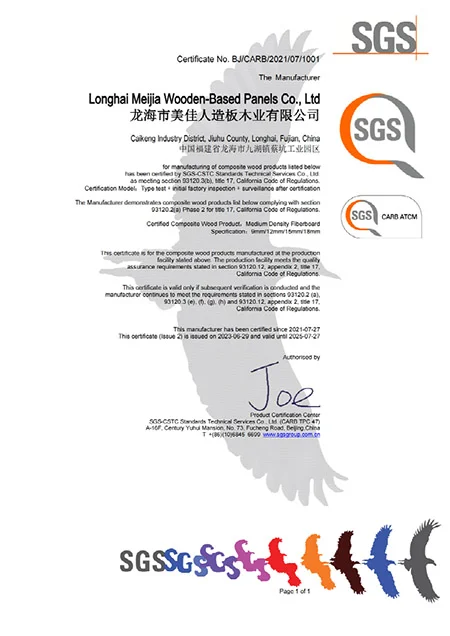

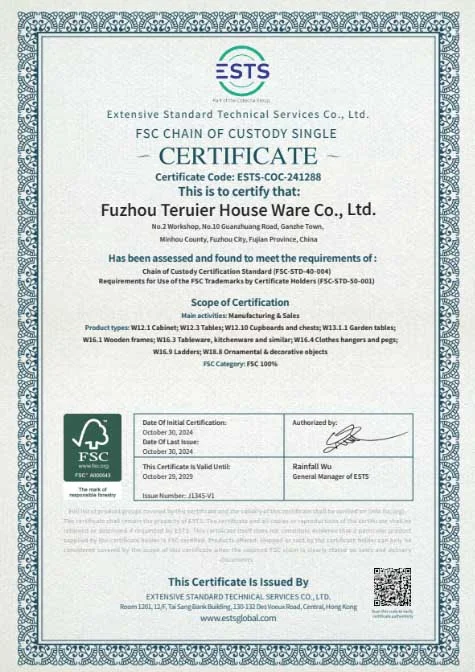

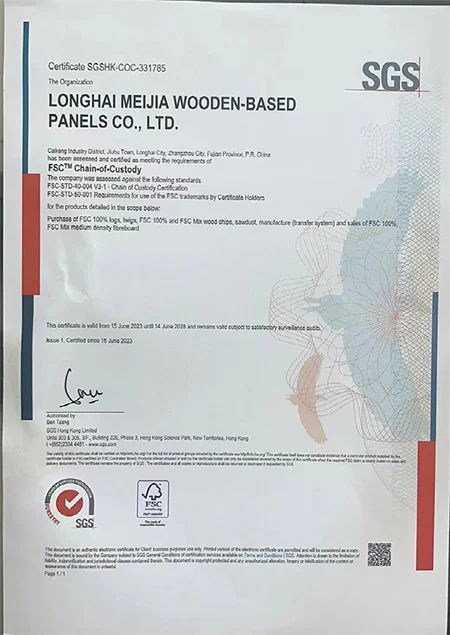

International Standards: Our mirrors meet or exceed international quality standards for corrosion resistance (e.g., ASTM B117 salt spray test standards).

Partner with the Trusted Supplier for Your Project

Do not let the corrosive environment compromise your design vision or maintenance budget. Investing in purpose-built mirrors from a dedicated supplier for anti-corrosion mirrors is the most cost-effective solution long-term.

Contact Teruiermirror today to discuss your project requirements, request free samples, or get a detailed quotation. Let us provide you with the durable, clear, and reliable mirror solution that your coastal project in Saudi Arabia deserves.

Visit our website at teruiermirror.com to learn more about our full product range.

Customer Reviews

Generally speaking, our order requirements are as follows: the minimum order quantity (MOQ) for large items is 50 pieces, for regular items it is 100 pieces, for small items it is 500 pieces, and for very small items (such as ceramic decorations) the MOQ is 1,000 pieces. Orders exceeding $100,000 will receive a 5% discount. The delivery timeline is determined based on the specific order quantity and production schedule. Typically, we are able to complete delivery within two months.

Leave a Reply