- Mirror Manufacturer USA-Custom Bathroom & LED Mirror Factory

- Mirrors French

- Mirror Austrian

- Canadian mirrors

- Mirrors British

- Mirror Dutch

- Mirror Hungarian

- Mirror Belgian

- Mirror Slovak

- Mirror Luxembourg

- Mirror Romanian

- Mirror Swiss

- Mirror Bulgarian

- Mirror Croatian

- Mirror Irish

- Mirror Serbian

- Mirror Swedish

- Mirrors Norwegian

- Mirrors Finnish

- Mirrors Danish

- Mirrors Icelandic

- Mirrors Greek

- Mirrors German

- Maltese mirrors

- Mirrors Italian

- Mirrors Cypriot

- Mirrors Spanish

- Mirrors Polish

- Mirrors Portuguese

- Mirrors Czech

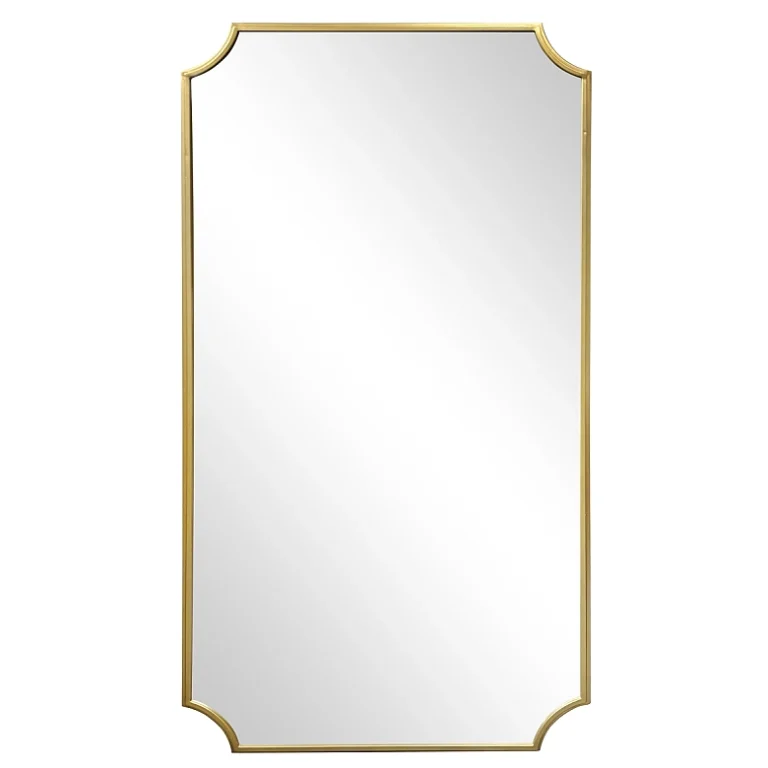

Vanity Mirror Manufacturer in China for US Market

I didn’t set out to find a vanity mirror manufacturer in China.

At the time, I was managing bathroom product sourcing for a US-based home brand, and like many procurement managers, my priorities were straightforward: stable quality, predictable lead times, and a supplier who wouldn’t disappear after the first shipment.

The challenge wasn’t design. It was execution.

When Domestic Options Fell Short

Our vanity mirror line was expanding faster than expected. What worked for small batches no longer worked at scale. Domestic suppliers were reliable, but pricing and capacity became bottlenecks. Overseas options looked attractive on paper, but experience had taught me to be cautious—especially with products as fragile and specification-sensitive as vanity mirrors.

That was when we started evaluating vanity mirror manufacturers in China for the US market.

Among several factories, one stood out early in the process: Teruiermirror.

First Conversations That Felt… Different

The initial calls weren’t sales-driven. No aggressive promises. No vague claims.

Instead, the team asked practical questions I wasn’t used to hearing from overseas suppliers:

-

How would these mirrors be installed in US bathrooms?

-

Were they shipping to retail distribution centers or job sites?

-

Did we need packaging suitable for e-commerce, or palletized bulk shipments?

-

Which states were our main markets?

Those questions mattered. They signaled experience.

Teruiermirror was clear about one thing from the beginning: they were a China-based vanity mirror manufacturer serving the US market, not a US company and not a trading intermediary. That transparency actually made the conversation easier.

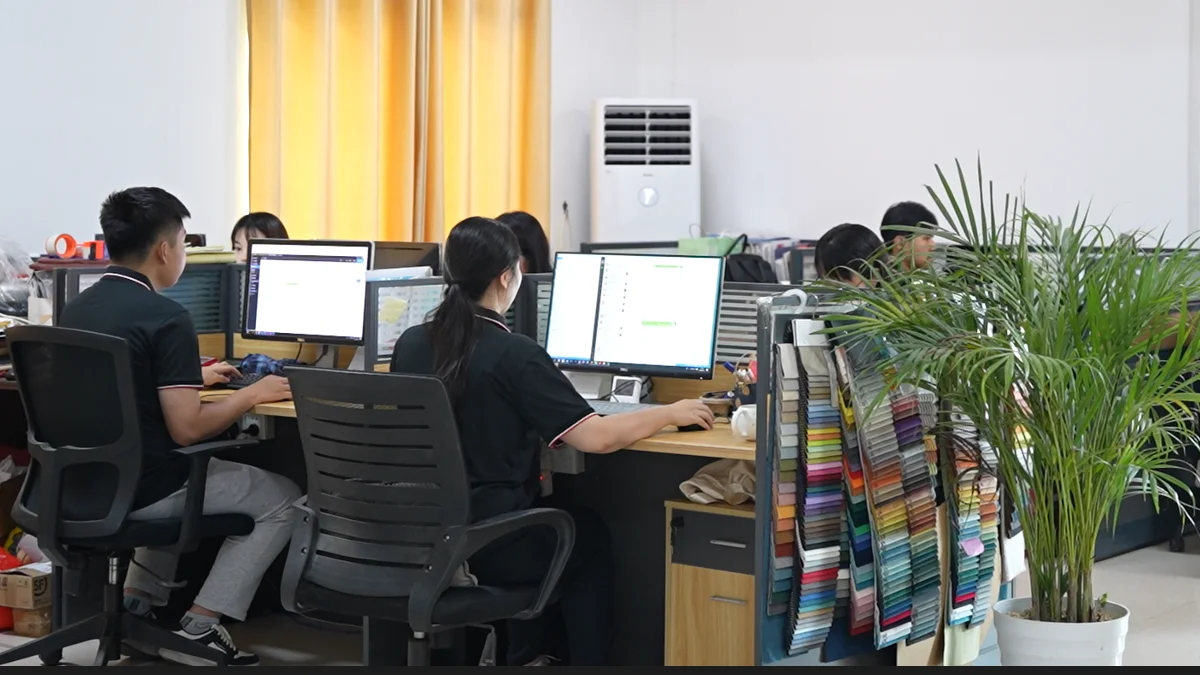

Manufacturing That Matched US Expectations

Samples came in clean and consistent. The glass clarity met our requirements. Edge finishing was smooth. Backing materials held up in humidity testing.

But what impressed me most wasn’t the sample—it was the consistency that followed.

Batch after batch, dimensions stayed within tolerance. Packaging didn’t change without notice. Mounting hardware remained compatible with US installers’ expectations. When minor adjustments were needed, they were handled at the factory level without delays or confusion.

This wasn’t a supplier reacting to instructions. It was a manufacturer anticipating them.

Designed in the US, Built in China

From a procurement standpoint, Teruiermirror functioned like an extension of our supply chain.

Our design concepts were shaped by US consumer preferences—clean lines, neutral finishes, practical sizes. Teruiermirror translated those ideas into manufacturable products using their in-house production capabilities in China.

Frames, coatings, mirror thickness, backing structure—everything was discussed with durability and real-world usage in mind. These weren’t decorative showroom pieces; they were vanity mirrors meant to survive daily use in American homes, apartments, and hospitality projects.

Why the Partnership Lasted

Over time, Teruiermirror became the kind of supplier every procurement manager hopes for: quiet, consistent, and dependable.

They never positioned themselves as a brand competing with ours. Their role was clear—to manufacture vanity mirrors in China that met US market standards and allowed our brand to grow without supply disruptions.

Even now, when new sourcing options appear, I measure them against that experience.

A Practical Conclusion from the US Side

Choosing a vanity mirror manufacturer in China for the US market isn’t about chasing the lowest cost. It’s about finding a factory that understands how American buyers think, test, and scale products.

From my experience, Teruiermirror earned that role by focusing on manufacturing fundamentals, honest communication, and long-term reliability—not marketing noise.

For a procurement manager, that’s what really matters.

Customer Reviews

Generally speaking, our order requirements are as follows: the minimum order quantity (MOQ) for large items is 50 pieces, for regular items it is 100 pieces, for small items it is 500 pieces, and for very small items (such as ceramic decorations) the MOQ is 1,000 pieces. Orders exceeding $100,000 will receive a 5% discount. The delivery timeline is determined based on the specific order quantity and production schedule. Typically, we are able to complete delivery within two months.

Leave a Reply